The list of our sweepers, washers and sprayers with tanks that are usually filled with water is long: Flexigo, Swingo, Cleango, SK, CityJet, Straliq CityJet, Senior, Wasa, MSH and more. In addition to their day-to-day business, our colleagues in charge had to deal with a large number of queries in the past few days concerning the material compatibility of a wide range of disinfectants. There are no official recommendations, so each authority decides independently whether and, if so, which substances will be used for disinfecting large areas.

When asked which substances can be used in our machines without hesitation, Tobias Weissenrieder, responsible for Product Management and R&D at the Aebi Schmidt Group, shows us a printout of a long list of products and substance compositions in front of the camera in the video conference: “Quite a few customers intend to use virucides or chlorine. However, when doing a closer examination of the composition, one quickly realises that at most the names are similar, but hardly any products are comparable with each other”. Our experts have learned in a short period of time that recommendations regarding material compatibility can only be made if the exact composition is known. And the list of tested products is getting longer every day.

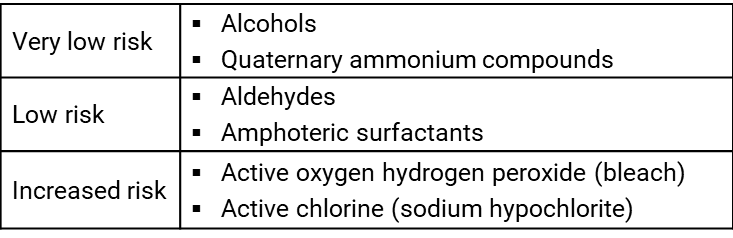

“But, over time patterns can be seen in the composition of the demanded active ingredients,” says Tobias Weissenrieder. He and his team have divided the six most common active ingredients into three risk levels (see table below). The risk refers to possible damage to components of individual parts as well as components thereof (for example, membranes or sealing rings).

Depending on the concentration, basically all the above-mentioned components can be used. Usually the tanks in the machines are made of plastic, but in some cases also of aluminium, stainless steel or steel. However, in any case the tanks must be completely and sufficiently rinsed with fresh water after each operation, at the latest after the completed day shift. In addition, virucides and biocides may require further action or precaution according the advise or regulation of the disinfectant manufacturer.

If you plan to use one of our machines with disinfectant, please approach your contact person at Aebi Schmidt. We will be pleased to provide you with advice and support with regard to material compatibility and protect you from unpleasant surprises after use.